FAST BUILDING

The Bampf 3-D Extreme

is > 95% Pre-built to get

you out and flying as

quickly as possible

GSRC does the following assemblies already for you:

(Click on each piture to see additional detailed pictures)

|

COWL

The Bampf 3D cowl is Pre-painted and all the required air vent holes are pre-cut, including the spinner opening, prior to painting. The mounting holes are pre-drilled and ready to mount. |

|

Landing Gear

The T6 aluminum gear is powder coated, pre-drilled to exactly align with the holes in the fuselage and the wheel pants. The whole gear assembly goes together in minutes. |

|

Canopy

The Bampf's canopy is already mounted securely to the fuselage and is painted with clean, crisp lines to match the overall colors. Is its not necessary to assemble the canopy what so ever. |

|

Fewer Parts to Assemble

The Bampf's was designed to have the minimum number of sub-assemblies to put together. The assembly is intuitive for the experienced builder and there is a >110 illustration ass'y manual. |

|

Functional Units Pre-Packaged

The Bampf's assembly is enhanced by putting each assembly step in its own individual package making them easy to find and assemble. No mixing or lost parts. |

|

Wing Servos

The Bampf's wing servo & control horn mount is highly engineered for strength, accurate control and ease of assembly. It only takes a few minutes to assemble. |

|

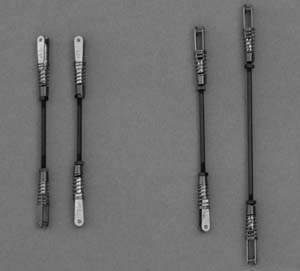

Push Rods

The Bampf's push-rods are pre-assembled and the clevises are within a turn or two of the correct length. Just snap the clevises onto to control horn and servo arm, tighten the locking and you're done. |

|

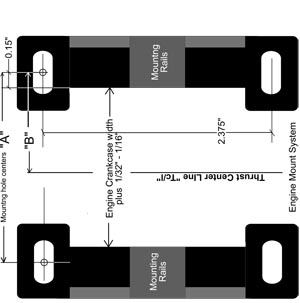

Engine Mounts

The Bampf's engine mount is designed with slotted mount holes. There is sufficient travel to accommodate a 60 2/s to a 180 4/s with out having to re-drill the firewall and re-attached the mounts to use with a great variety of engine sizes. This also allows the entire mount and engine to be easily adjusted for perfect alignment of the engine and spinner to the cowl face. |

|

Wing Assembly

The Bampf's two wing panels are designed to easily assemble together without the need for special jigs or alignment procedures. Simply epoxy the two panels together with the root edges held flush, and the incidence at the tips will be within 1/4 degree! |

|

Control Horn Installation

The Bampf's control horns need only four (4) screws into the hard- wood block to hold tight. There is no need to drill thru the surface to make difficult alignments to opposite surface plates or nuts, etc. |